Centre of Excellence on E-waste Management: Centre of Excellence (CoE) on E-waste management is established at C-MET Hyderabad on public private partnership (PPP) model with funding ratio of 40:40:20 from Ministry of Electronics and Information Technology (MeitY), Government of Telangana and Private industry. The basic objective of the centre is to create physical infrastructure and cost effective recycling technologies to manage India’s e-waste and thereby promote resource efficiency and circular economy in the country. Various e-waste recycling technologies and necessary processing equipment for the same are successfully developed by the centre at pilot plant scale and intellectual properties were protected by filing patents. The major areas of R&D activities under the centre include:

- Recovery of valuable metal contents from discarded lithium ion batteries (LIBs);

- Extraction of rare earth elements (REE) from spent permanent magnets;

- Recycling of spent Printed Circuit Boards for effective recovery of precious metals such as gold, silver, palladium, copper etc., and

- Recovery of valuable materials from End of Life (EoL) Silicon Solar cells.

In addition, the centre also promotes human resource development through M. Tech and PhD. Programmes on E-waste Resource Engineering and Management jointly with IIT Hyderabad.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self-sustenance

(in Rs Lakhs) |

| 802 | 08 | 32 | 03 | 01 | 12 | 01 | 8.27 |

For more details please visit centre website at https://www.coeonewaste.com/index.html

CoE on Rechargeable Battery Technology (Pre-cell): Lithium Ion batteries are ideal power source for consumer electronics, e-mobility and power sectors. These batteries are also expected to find niche applications in e-governance electronics such as VVPAT machines. Current energy storage market in India includes applications such as mobile handsets and their accessories, solar rooftop, grid solar integration, wind integration, electric vehicles, inverter back-ups, telecom, UPS, rural micro-grid and off-grid applications, diesel replacement, railways etc. India has vibrant Lead Acid battery manufacturing industry and needs to augment Li-ion battery cell manufacturing to meet current and future demands of energy storage. India primarily imports Li-ion cells and manufactures battery packs of different capacity for various applications. Government support in form of R&D funding for development of cost-effective end-to-end indigenous technology for manufacturing of rechargeable battery (Li-ion and post lithium) suited for Indian environment is vital for meeting the future demands. The support for R&D is expected to lower up-front investment cost, utilize Indian supply chain, improve profit margin and bring SMEs into play for manufacturing industrial units of rechargeable battery cell manufacturing eco-system. In this direction, MeitY has initiated a self-sustainable R&D centre entitled “Centre of Excellence (CoE) on Rechargeable Battery Technology (Pre-cell)” at CMET, Pune for scale up and transfer of indigenous technology on Lithium ion battery and Sodium ion battery (post lithium) to Indian SMEs for manufacturing of battery cells.

Vision of Centre: Nurture Indian industry for manufacturing of rechargeable battery cell (Li-ion/Nation) in India.

Mission of Centre: To build capacity in all verticals of Indian rechargeable battery cell (Li-ion/Na-ion) manufacturing eco-system through focused and coordinated R&D.

Scope of Centre: Safe, sustainable and cost-effective indigenous technology suited for Indian environment (temperature, humidity, product usage pattern, recyclability etc.) and businesses (investment cost, supply chain and start-ups).

The centre provides R&D services to industry and indigenous technology solutions from material to cell manufacturing.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self- sustenance

(in Rs Lakhs) |

| 110 | 14 | - | 05 | - | 25 | 01 | 54.57 |

For more details please contact dr[dot]sankhadipdas[at]meity[dot]gov[dot]in

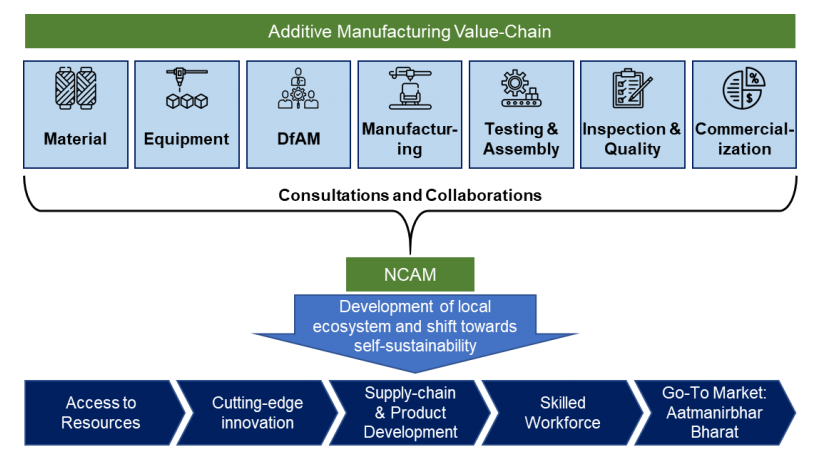

CoE on Additive Manufacturing- Optoelectronics Sector: Additive Manufacturing (AM) is disruptive set of technologies which are bringing fundamental change in how manufacturing is carried out in many sectors due to its ability for mass customization. AM is enabler for digital manufacturing which has capability in producing products directly from design data by adding layers of material to obtain the final shape with minimal waste, supporting Industry 4.0. Ministry of Electronics and Information Technology (MeitY) has initiated a Centre of Excellence on Additive Manufacturing at Centre for Materials for Electronics Technology (C-MET), Pune in collaboration with Central Institute of Plastics Engineering & Technology (CIPET), Bhubaneswar. The objectives of the centre are to support Indian Additive Manufacturing Eco-system through focused and coordinated research, design and development in collaboration with 3 participating industries. The centre is expected to achieve self-sustenance and focus on developing indigenous materials and machine technologies for electronics manufacturing sector. In current phase of the project, 4 technologies with 4 different machines, 13 materials and 4 different electronics application products are slated to be developed. The project is also bringing opportunities for Indian companies to develop their own AM material and machine technologies for global market at much reduced R&D cost for any sector (not limited to electronics) such as aerospace, medical, automotive etc. The centre is also training manpower to support growth of AM economy in India.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self- sustenance

(in Rs Lakhs) |

| 37 | 6 | 1 | 4 | - | 3 | 3 | 6 |

For more details please contact shany[at]cmet[dot]gov[dot]in

Centre for Programmable Photonic Integrated Circuit and Systems (CPPICS): Field programmable photonic gate array (FPPGA) core technology is a multipurpose photonic processor platform which can cater to multiple sectors with multiple applications such as quantum computing, quantum communication, 5G/6G communications, IoT, radar and avionics etc. Ministry of Electronics and Information Technology (MeitY) has initiated a Centre for Programmable Photonic Integrated Circuit and Systems (CPPICS) at IIT Madras in collaboration with industry to design, manufacture and develop applications based on FPPGA cores using Silicon Photonics. The centre is slated to become self-sufficient in 5 years time, commercialize the products through Start-up and train manpower to boost the eco-system of such manufacturing. The centre is collaborating with M/s Si2 Microsystems, Bangalore for System-in-Package solutions for the proposed silicon photonics FPPGA cores which will create commercially viable products for proposed start-up.

Currently, the centre is actively involved in photonics chip tape outs through established silicon photonics foundries, namely AMF Singapore and IMEC Belgium. The first chip has been taped out in AMF Singapore.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self- sustenance

(in Rs Lakhs) |

| 22 | 5 | 0 | 0 | 0 | 1 | 0 | 0 |

For more details please visit centre website at https://cppics.iitm.ac.in/

CoE on Additive Manufacturing: Medical Device Sector

Additive Manufacturing (AM) is disruptive set of technologies which are bringing fundamental change in how manufacturing is carried out in many sectors due to its ability for mass customization. AM is enabler for digital manufacturing which has capability in producing products directly from design data by adding layers of material to obtain the final shape with minimal waste, supporting Industry 4.0. Ministry of Electronics and Information Technology (MeitY) has initiated a Centre of Excellence on Additive Manufacturing at Andhra Pradesh MedTech Zone, Vishakapatnam, Andhra Pradesh which will support Medical Device Sector. The vision of the centre is to make COE at AMTZ a hub (common facility for local AM industry which will offset disabilities for competing with global peers) for medical device innovation in India by nurturing various medical device start-ups through Additive Manufacturing (AM) technology. Through this centre sustainable long-term ecosystem will be provided to start-ups and industries which will enable medical device innovation in India; build skill-sets in the AM industry, in particular AM in the medical industry to achieve competitive advantages in the global market; promote creation of Indian IPR & facilitate IPR filing activity and offer industry, academia, global linkages to provide market access to the incubated products.

The CoE has shown good results within one year of its establishment: both in skill development and technology development. Over 364 manpower were trained in 3D printing, Medical Device Design, Prototyping and Testing in CoE AM - MDS. CoE is successful in establishing production of materials and products which earlier were under import dependency. One of the key product is UHMWPE, a novel orthoplastic engineered for its weight-bearing properties. This has been the major liner component for orthopaedic implants in hip and knee arthroplasty. The CoE also created capacities to deliver the highest quality small metal components with outstanding levels of chemistry control, strength, and density across a wide range of alloys.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self- sustenance (in Rs Lakhs) |

| 364 | 2 | 5 | 2 | 3 | 2 | 5 | 92 |

For more details please visit centre website at https://www.linkedin.com/company/center-of-excellence-for-additive-manufacturing-medical-device-sector-coe-am-mds/

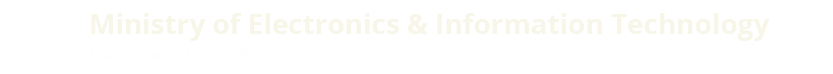

CoE on products based on Li-ion (Post Cell):

Lack of design capability in Indian mobile handset and accessories manufacturing severely hampers domestic companies to introduce new models, customize features for the customers which leaves the market wide open to competitors having this coveted ability. India is also losing valuable foreign exchange to international design hubs in other countries. Thus for long term success of Indian electronics manufacturing, research and innovation supporting design centre needs to be based in India. The setting of industrial parks, creation of eco-system for electronic industries may be the only solution to reduce the import dependency. To make India self-reliant and Aatma Nirbhar in this sector, a Centre of Excellence (CoE) on Post-cell value chain for power bank technology is proposed to be set up at C-DAC Noida with the requisite infrastructure, equipment, R&D facilities etc. The CoE is expected to seed a design hub for SMEs in the power bank industry and other Indian mobile handset and accessories eco-system products based on Li-ion cells, leading to reduced foreign exchange outgo and employment generation.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self-sustenance (in Rs Lakhs) |

| 05 | - | - | 02 | - | 02 | 02 | - |

For more details please visit centre website https://coenoida.com

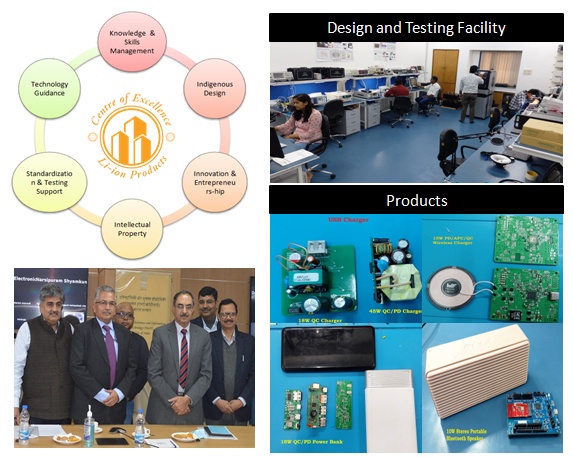

National Centre on Additive Manufacturing (NCAM)

Ministry of Electronics and Information Technology (MeitY) launched a strategy paper entitled “National Strategy on Additive manufacturing (AM)” for promoting various verticals of the AM sector, including machines, materials, software and designs to leverage the untapped business opportunities that will unfold in the near future. The strategy aims at promoting the creation of a conducive ecosystem for design, development and deployment, and to overcome technical and economic barriers for local manufacturers to seamlessly adopt Additive Manufacturing. This is also expected to facilitate the creation of a support base of domestic manufacturers for setting up operations with supporting ancillaries in India by foreign companies as well as Global AM leaders. The strategy on AM identified the need to establish a National Additive Manufacturing Centre to spearhead the National Initiative for positioning India at the forefront of development and adoption of Additive Manufacturing Technologies. The “National Centre for Additive Manufacturing (NCAM)” has been initiated with Telangana State Government at Hyderabad. The NCAM is a company registered under section 8(1) of the Companies Act 2013. The vision of NCAM is to create and enable a sustainable ecosystem for product innovation in India with emphasis on research, design, development, and testing through collaborative efforts between academia, industry and government using the disruptive technology of Additive Manufacturing. It is aimed to develop a comprehensive Additive Manufacturing ecosystem in the country and position India as a Global AM Manufacturing Hub

To achieve its mandate of developing the local ecosystem, the responsibilities of NCAM is broadly captured in the following five pillars:

Since its inception the centre has carried out the following:

- Finalised the NCAM Roadmap & 5-year charter. The roadmap has been approved by the subcommittee formed by NCAM.

- MOU grounding with five key industrial & academic players with clear specific objectives & outcomes. These proposals are to be discussed with ERC for further action accordingly.

- Organised 4+ Expert Additive Sessions and ups killed 1000+ working professionals in partnership with AM Chronicle, HITEX, ASTM, HP & Redington.

- Organised a knowledge forum on medical 3D printing opportunities in India along with Materialise NV which is the largest medical additive player in the world.

- Launched National Skill Development Awareness Marathon and Training Program across 6+ cities in India to train 2500+ individuals. Three sessions have been successfully conducted in partnership with Lovely Professional University Punjab, St. Vincent Pallotti College of Engineering & Technology Nagpur and Marathwada Mitra Mandal's College of Engineering Pune

- Organised Start-up as a business opportunity symposium at AMSI event in Bangalore on 15th of October 2022.

- The Faculty Development Program on ‘Overview of Global Metal 3D Printing Technology, Current state in India & the Future Research Areas’ was organised in collaboration with Dayanand Sagar Institute Bangalore on the 15th of October 2022 under the AICTE ATAL Faculty Development Programme. In this event, more than 50 faculties joined.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self-sustenance (in Rs Lakhs) |

| 1795 | - | - | - | - | 30 | 25 | - |

For more details please visit centre website https://ncam.in/

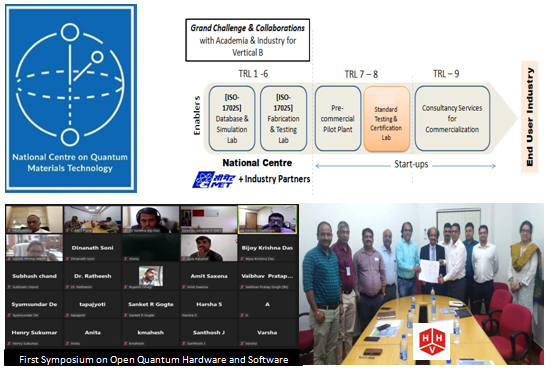

National Centre for Quantum Manufacturing Technology:

Naturally occurring quantum effects have given humanity electronics that are the basis of controls in telecommunications, media, computing, industrial automation etc which influences our daily digital lives. Engineered quantum effects are the basis of next generation Quantum Technologies (QT) and are expected to have immense impact on finance, defense, aerospace, energy, telecommunication, imaging and computing sectors in the coming decade through core technology advances of precision timing, sensors and computation. In daily life, such technologies are expected to have profound effect through 5G and 6G communications (mobiles and their cyber security) and computing requirements such as big data & supercomputing, in India. To realize the benefit of quantum technologies, India must succeed in converting its research into innovative and marketable products. In this direction, PRIME MINISTER'S SCIENCE, TECHNOLOGY AND INNOVATION ADVISORY COUNCIL (PM-STIAC) MISSIONS includes Quantum Frontier Mission which is focusing on development of quantum computers, quantum chemistry, quantum communication, new materials, quantum sensors, and quantum cryptography. The base of QTs is cost effective materials which will allow room temperature operations and miniaturization of QTs or Quantum Materials (QM). Immediate key challenges for the QMT field in India are:

R&D Challenges: Quantum Material Technologies (QMT) needs to provide high quality, reliable and reproducible materials which can aid in high temperature operations and miniaturization for QTs with cost effective ways to manufacture. Holding key IPRs on QM and its processing technologies & machinery will be vital for creating marketable products. Sustained joint efforts of Industry and academia are much needed for success of such marketable products. QMT will require a good innovation network, supported by R&D infrastructure from TRL 1 to TRL 9, national & international collaborations which can reduce time to market for QT products. Hence, sustained Government investment and high growth rate of industry will be required this decade and beyond to help bring QM products to global and local market.

Manpower development: The transition of QMT into commercial products will require a new generation of quantum engineers – specialists in physics, engineering, photonics, electronics or computer science who are conversant in multi-disciplinary and systems-based approaches, possess the right entrepreneurial and business skills, and are able to adapt to new jobs and roles in the emerging industry and academia. Sustained Government and industry efforts in the development of Quantum workforce that meets the needs of future industry and academia will be vital for building a manufacturing eco-system of QMT in India.

Technology Roadmap: QMT is a vast field and for marketable QM Products & technologies focus needs to be maintained during R&D phase. Concentrating on material requirements for core QT fields of precision timing, sensors and computation will provide focus material development which can then be the basis for application development in the fields of finance, defence, aerospace, energy, telecommunication, imaging, cyber security and computing sectors. A persistent roadmapping activity should be part of any Government investment of QMT R&D.

To address these challenges a “National Centre for Quantum Material Technologies” [NCQMT] has been established at CMET, Pune which is expected to deliver aim of development of quantum material technology to applications and their transfer of technology to industry with market acceptable time to market. The centre is slated to encourage R&D in Quantum Technologies by assisting R&D institutes and academia through a Grand Challenge and supply of indigenous materials with in first five years (Phase I). The centre is currently establishing two ISO17025 standard labs: a) Fabrication and Testing Lab and b) Database & Simulation Lab. NCQMT has signed MOU with M/S Hind HiVacuum Company Pvt. Ltd, Bangalore with an objective to manufacture process and machines based on the India Supply Chain for the global market.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self-sustenance (in Rs Lakhs) |

| 10 | - | - | - | - | 1 | - | - |

For more details please visit centre linked in page: https://www.linkedin.com/in/national-centre-on-quantum-materials-technology-at-cmet-pune-45472324b/

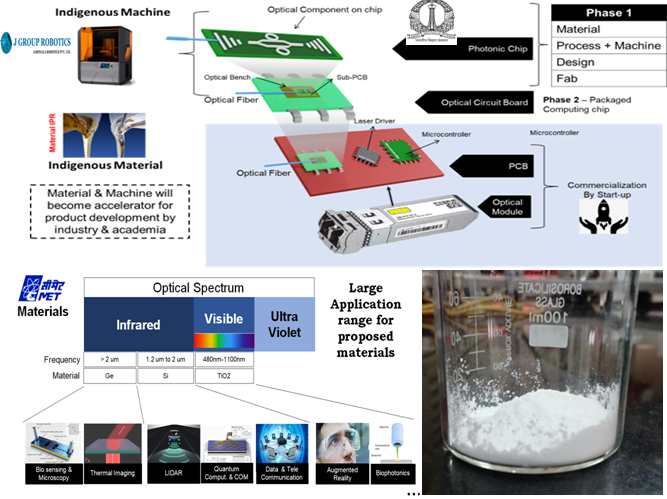

Centre for Promotion of Additive Manufacturing: Optical Computing Chips

Optical computational chips and photonic devices finds application in various fields of technologies such as communication, computation, healthcare, automation, sensor and defence. However, although they have shown plethora of applications, their industrial viability is mainly limited by their fabrication process which involves presence of foundries, numerous process-equipments and steps. In recent years, Additive Manufacturing (AM) processes are bringing fundamental change in how manufacturing is carried out in many sectors due to its ability for scalable, cost effective and sustainable fabrication process. AM is an enabler for digital manufacturing which has capability in producing products directly from design data by adding layers of material to obtain the final shape with minimal wastage. The Ministry of Electronics and Information Technology (MeitY) has initiated a centre on Additive Manufacturing based Cost Effective Optical Computing Chips at Indian Institute of Science, Bangalore (IISc) in collaboration with Centre for Materials for Electronics Technology (C-MET), Pune.

The objective of the centre is to design and fabricate global state of the art 3D printer to achieve sub-micron resolution, indigenous materials for printing and to design and fabricate optical devices for computation. The centre is expected to achieve self-sustenance and focus on developing indigenous materials and machine technologies for photonics manufacturing sector. The centre is also bringing opportunities for Indian companies to develop their own AM material and machine technologies for global market at much reduced R&D cost for any sector (not limited to photonics) such as aerospace, medical, automotive etc. The centre is also going to train manpower to support growth of AM economy in India.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self-sustenance (in Rs Lakhs) |

| 17 | 0 | 0 | 1 | 0 | 1 | 1 | 0 |

For more details please contact tapajyoti[at]iisc[dot]ac[dot]in

Centre of Excellence (CoE) in Intelligent Internet of Things (IIoT) Sensors

Centre of Excellence (CoE) in Intelligent IoT Sensors is being established at Centre for Materials for Electronics Technology (C-MET), Thrissur in collaboration with Indian Institute of Information Technology & Management Kerala (IIITM-K). The main objective of CoE is to establish state-of-the-art facilities for sensor manufacturing, intelligent sensor system hardware, AI software development etc. The entre will host an incubation facility for startups in IIoT sensors and promote innovation and entrepreneurship through grand challenges.

A spectrum of IoT products were developed under the centre and are ready for commercialization. Indigenous technology for the development of chip thermistors and chip thermal sensor was transferred to M/s Thermosen Technologies Pvt. Ltd, Bangalore based on the technology developed at C-MET. The grand challenges were floated in the domains of Disaster Management, Robotics & automation and Smart cities.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self-sustenance (in Rs Lakhs) |

| 123 | 0 | 10 | 3 | 1 | 10 | 3 | 10.08 |

For more details please contact seema[at]cmet[dot]gov[dot]in

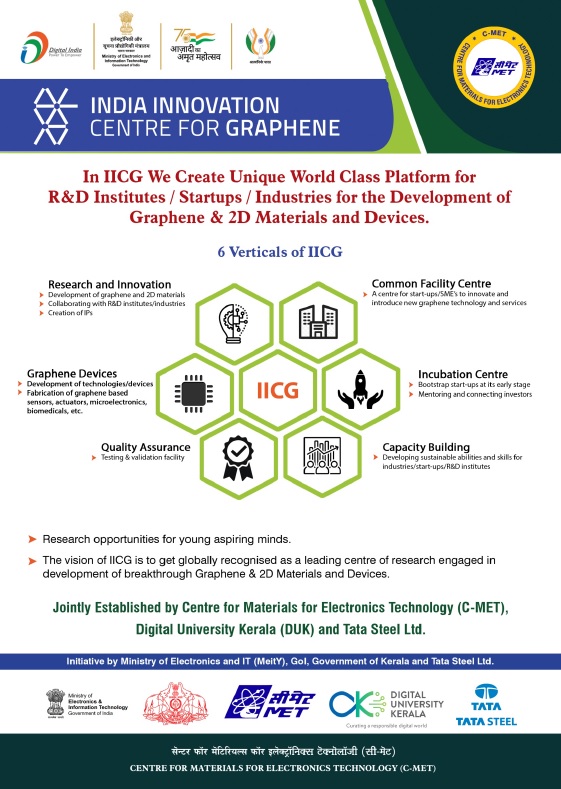

India Innovation Centre for Graphene

The India Innovation Centre for Graphene (IICG) is being implemented at Centre for Materials for Electronics Technology (C-MET), Thrissur in collaboration with Digital University Kerala (DUK) and Tata Steel Limited (TSL). The centre is financially supported by MeitY, Government of Kerala, TSL and industries. IICG is envisioned to investigate the science and technology of graphene and other 2D materials. This centre envisages partnering effectively with industrial-academic activities to promote innovative and adventurous research emphasizing applications. IICG will attract internationally leading research on graphene into India and bridge the gap between scientific development and industrial applications of graphene in our Nation. The institute is under the process of creating class 100 clean room facilities and sophisticated equipments to promote research in alignment with industry requirements.

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self-sustenance (in Rs Lakhs) |

| 50 | 0 | 3 | 0 | 0 | 2 | 0 | 0 |

For more details please contact seema[at]cmet[dot]gov[dot]in

Centre of innovation & a Manufacturing Eco-System for Sensors (CIMES) in Industrial IoT

CGCRI Kolkata is implementing a proposal on Establishment of a Centre of Innovation & a Manufacturing EcoSystem for Sensors (CIMES) in Industrial IoT" to promote start-ups/entrepreneur Industry 4.0 in the country. The proposal aims to create Innovative IoT sensors for industrial applications, promote manufacturing ecosystem through a business incubation, commercialization sensors technologies in structural & geo-technical instrumentation areas. Output & Outcome includes a sustainable R&D & manufacturing support to industries working in geotechnical & structural instrumentation & structural health monitoring for industrial IoT. End-to-end solution from materials, technologies, system design, packaging, strategy for field deployment, Creation of start-ups/SMEs with a synergy of Govt. of West Bengal's technology/manufacturing hub & also other states, Services to industries on creation & maintenance of mega civil eng. infrastructure, mining safety, railway infrastructure & automation, Creation of State of art testing lab for standards, certification for components, systems for revenue generation, Creating 500 skilled manpower for relevant industries are other highlights.

Major outcomes also include an incubator facility with > 10 entrepreneurs, Grand Challenge for > 10 products targeted for industrial IoT domain, Creation of > 2 local IPs/ annum to reduce the import burden, Launching of > 5 products, ToT > 10 commercialization ready products to industry, Ensuring self-sustenance through financial contribution from industry, the start-ups and institution in strategic sector in the area of specialty sensors, turnkey project implementation.

Major industry commitment obtained from in the project are from NTPC, BHEL, TATA Steel, L&T, Hindustan Zinc Ttd, Safety & Disaster Mngt Dep. Govt. of WB, ISRO, DRDO. The project has been supported by West Bengal Electronics Industry Development Corporation Limited (WBIDCL) and Indian Institute of Management Calcutta Innovation Park (IIMCIP).

Output and Outcome (till October 2022)

| Number of Specialized Manpower Trained | Number of publications | Number of Proof of concept leading to field deployment | Number of IPRs filed | Number of Transfer of Technology (ToT) to industry | Number of industries engaged | Number of start-ups engaged | Revenue Generated for Self-sustenance (in Rs Lakhs) |

| 12 | - | 1 | - | - | 5 | - | - |

For more details please contact sandip[at]meity[dot]gov[dot]in