Mission: R&D to support policy & strategy framing; technology development & commercialization for manufacturing; and techno-economical manpower generation in the areas of Electronics Materials & Components, Photonics, Circular Economy & E-waste, IoT Sensors and Additive Manufacturing & 3D Printing.

Social outreach: E-waste Awareness Programme, Providing technology & Skill development for informal sector and of SC/ST demography, Effort towards building products countering COVID-19 pandemic

EMCD R&D thrust areas:

- Electronics Materials & Components –

- Energy Storage: Rechargeable battery/cell, supercapacitors, hybrid packs etc.

- Printed Circuit Board Substrates and its applications: Electro-Magnetic Shielding; Antenna, SIW etc.

- Quantum Material Technology: Diamond Substrate, h-BN Crystals and films, NbN and NbTiN films on Substrate, 2D substrate and wafers, Quantum Dots, Graphene, SiC, SiN, Lithium niobate (LiNbO3) etc.

- Photonics– Silicon Photonics Chips, Polymer Photonic Chips, Integrated Photonics, Optoelectronic Packaging, Optical packaging, Optical Fibres, Lasers, Sensors etc.

- Electronics waste– PCB, Solar Cell, Lithium ion Battery, Magnets recycling technologies, skill development and awareness creation

- IoT Sensors - IoT Sensor Materials and applications

- Additive Manufacturing – Material, Machine and 3D printed products in various sectors such as optoelectronics components, medical device sector, photonic chips, digital toy, agro & food processing, sustainable smart packaging, environment and forest etc

EMCD R&D #

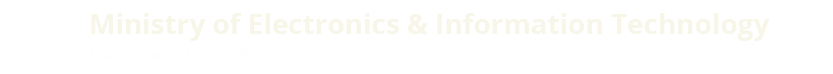

Electronics Components & Material Development Programme (EMDP) has been promoting research and development (R&D) activity since 1986 to nurture electronics development in the country for boosting local manufacturing. EMDP’s core areas of research are Electronics Materials & Components including Quantum Material Technologies, Photonics, Circular Economy & E-waste, IoT Sensors and Additive Manufacturing & 3D Printing. EMDP supported National MISSION under National Policy 2012 on Electronics: “Promotion of a vibrant and sustainable ecosystem of R&D design, engineering and innovation in electronics” during 2012 to 2018. EMDP is currently supporting National Policy on Electronics 2019 (NPE 2019): “Encourage industry–led R&D and innovation in all sub-sectors of electronics”. The strategy under this objective is to adopt top-down approach or market pull R&D to cater for local manufacturing needs in the optoelectronics (electronics and photonics) sector. EMCD’s outputs for promotion of R&D ecosystem are provided below:

Examples of some of the successfully developed technologies are provided below:

To support NPE 2019 and industry led R&D, EMCD is working with industries of different manufacturing sectors. Primarily, industry demands among other things include:

- Adequate, focused and long term govt. funding for R&D projects for economically viable prototype demonstrations and IPR generation in areas of Indian electronics manufacturing

- Focus R&D on indigenous product manufacturing technologies

- Make Govt. Transfer of Technology policies suitable for transferring to SMEs and MSMEs

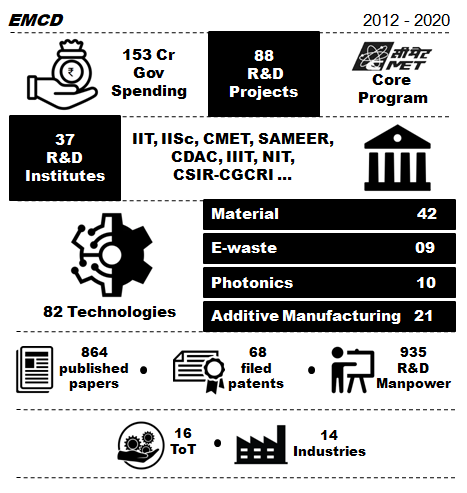

To cater to these industry demands MeitY is creating self-sustaining R&D centres or SRCs with industrial partnership where industry is playing key roles in technology road-mapping, administration, funding and self-sustenance of the R&D platform. Govt. is extending funding, knowhow, scientific manpower, laboratory access, and IPR (existing) for development of industry demanded product prototype, technology solutions and IPR generation followed by commercialization through ToT to industry and start-ups. In this direction, EMCD has initiated 12 centres with planned targets provided below:

In coming future EMCD program is expected to further support manufacturing especially in optoelectronics domain through additional such SRCs in EMCD thrust areas which can promote global contract research and R&D export.

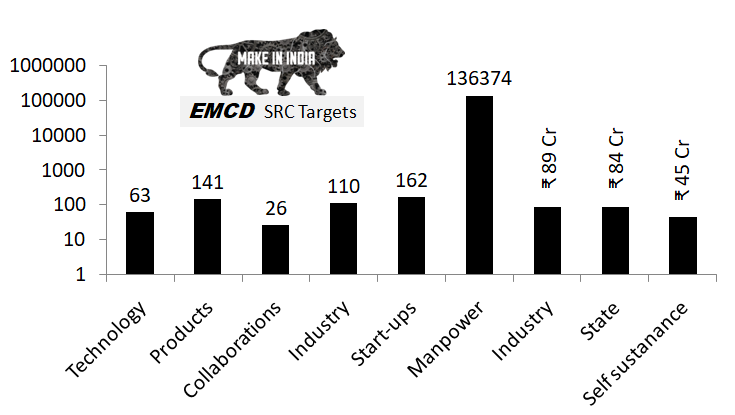

EMCD actively participates in policy & strategy research; and contributes towards national and international policy & strategy framing of Government of India. Since 2012, EMCD has contributed towards the following areas of policy & strategy:

EMCD Social outreach #

EMCD has been working on social outreach for last five years to raise awareness in general public on menace of E-waste and also promote entrepreneurship among socially weaker sections using EMCD developed technologies for electronics manufacturing.

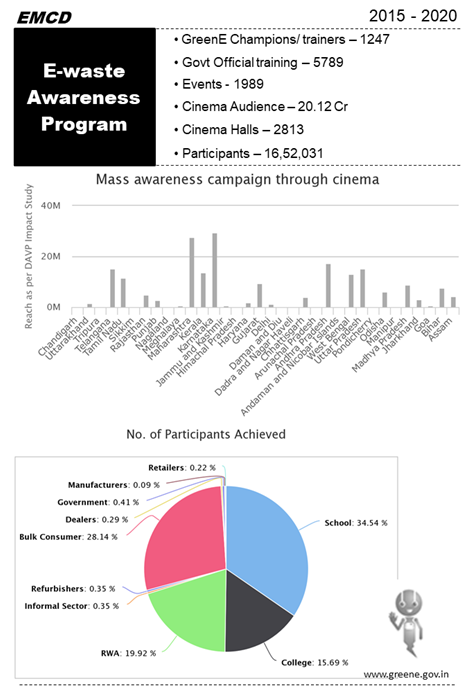

E-waste Awareness Program: The Ministry of Electronics & Information Technology (MeitY) has implemented “Awareness Programme on Environmental Hazards of Electronic Waste” during 2015 to 2020 to create awareness among the public about the hazards of e-waste recycling in informal sector on pan India basis. The programme had created training tools, content materials, films, printed materials, videos and jingles etc., for every strata of the society which are freely available on the dedicated website http://greene.gov.in/ and Greene app. Further, social media platforms (Twitter handle and Facebook page) and mobile app had also been created to provide online status of the activities and show-case the activities/ workshops/carnivals etc., conducted under the programme.

The programme was successfully able to conducted 1,918 workshops and activities in various cities in 31 States/UTs, which were attended by 16,52,031 participants from school, colleges, RWA, manufacturer, informal operators, bulk consumer, dealers and refurbishers etc., The programme had covered 5,789 Government officials in various States. Besides, 1,247 GreenE Champions/trainers had also been trained. The mass awareness amongst youth of the country, nearly 20.12 crore audience, had also been created by covering 2,813 cinema halls. Suitable course content on this subject for Standard 7 to 9 class students was also developed and handed over to the Ministry of Education using NCERT’s DIKSHA digital platform.

Skill & Entrepreneurship Development: EMDP programme has been building knowledge on electronics manufacturing for last several decades and as part of its outreach for weaker sections of the societies EMDP has initiated several projects on manpower training among SC/ST and North Eastern communities. These projects are supporting entrepreneurship programmes in the areas of supercapacitor based solar lanterns which can be charged in minutes, digital thermometer based on indigenous sensors, and E-waste management. Additionally, training for RoHS laboratory manpower has been initiated. In total, the outreach is for 16,440 citizens in 20 States. State Governments are also taking active participation in these projects through State Pollution Control Boards (SPCB) and Institute of Human Resource Development (IHRD). First batches of entrepreneurship programmes are already passing out and few are on process to establish MSMEs on manufacturing of digital thermometers.

EMCD effort towards building products countering COVID-19 pandemic: EMCD has been building efforts towards producing products for countering COVID-19 pandemic through Ministry’s Scientific Society of Centre for Materials for Electronics Technology(C-MET). In this regard following efforts are on-going:

- Development of low-cost polymer swab for COVID testing kits. Considering the acute shortage of testing kits in the country, Centre for Materials for Electronics Technology (CMET), Pune, scientific society of Ministry of Electronics and Information Technology has developed polymer swabs, consisting of polymer rod/stick and polymer fibers with locally sourced materials. Polymer rod is developed with thermoplastic polypropylene materials through injection moulding. Polymer fibers are then crimp pressed on the polymer rod. Sri Research for Tissue Engineering PVT. Ltd, Bangalore has carried out clinical and ethical trials. Result is satisfactory. Additive Manufacturing Society of India, Bangalore is now considering production of these indigenous kits in the country. A significant cost reduction is possible Italian substitutes.

- Development of indigenous technology of anti-viral and anti-bacterial masks. Centre for Materials for Electronics Technology (CMET), Pune, scientific society of Ministry of Electronics and Information Technology has developed anti-viral and anti-bacterial masks with metal/metal semiconductor nanoparticles like Ag[at]ZnO and Cu[at]ZnO as a cost effective alternative of N95 masks in Indian market. Yshawantrao Chavan Institute of Science, (YCIS) Satara has carried out testing of the masks for antibacterial properties and pathogen tests and shown encouraging results.

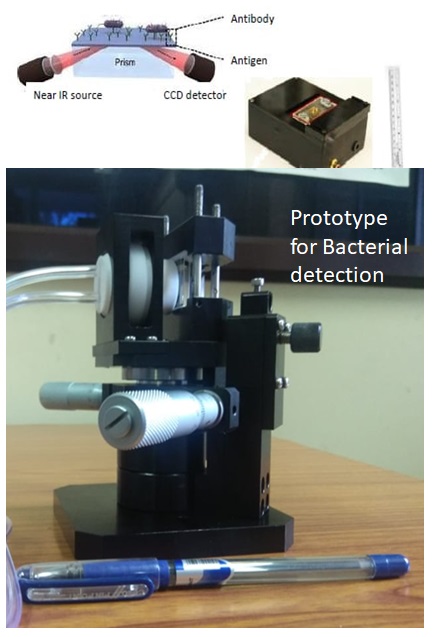

- Development of cost-effective point of care plasmonic portable sensor for covid 19 virus antigen in blood. Centre for Materials for Electronics Technology (CMET), Thrissur, scientific society of Ministry of Electronics and Information Technology CMET has developed a point of care plasmonic portable sensor with disposable semiconductor based chips to detect antibody with presence of covid 19 virus in blood. The sensor was tested for food borne pathogens by Rajiv Gandhi Centre for Biotechnology (RGCB), Thiruvananthapuram. Functionalization of the sensor and the docking efficiency analysis are being carried out on the designed bio receptors with different pathogenic strains. First version of the biosensor is under validation at RGCB. This technology is now being modified for antibody testing in blood for Covid 19 patient. Such portable devices would be extremely useful for random testing of patients at affordable cost.

- Digital thermometer for screening and patient temperature monitoring for COVID-19. Centre for Materials for Electronics Technology (CMET), Thrissur, scientific society of Ministry of Electronics and Information Technology CMET has developed an indigenous technology for making chip thermistors (thermal sensor). Most of the commercial digital thermometers are based on thermistors because they have good accuracy, fast response, rugged and safe. Based on this thermal sensor CMET has developed an indigenous technology for low cost fast response digital thermometers suitable for point of care temperature measurements for COVID patients. Further research is on-going for to modify the technology for screening of COVID-19 infection with disposal tips.

For further information please contact:

Smt Sunita Verma

Group Coordinator & Senior Director

R&D in Electronics Group

Phone: +91-11-24364464 (Office)

E-mail: sunita[at]meity[dot]gov[dot]in