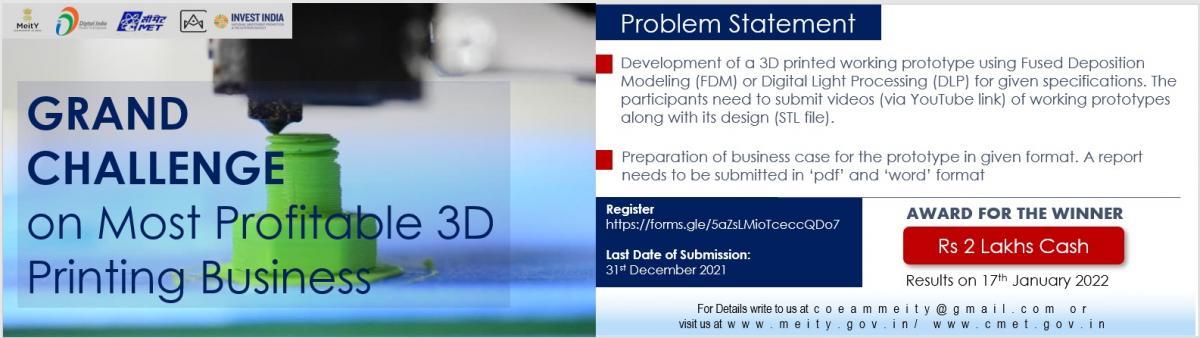

Toy manufacturing is heavily dependent on various technologies of moulding (injection moulding, blow moulding, rotary moulding etc) of plastic parts in India. The capital cost of machinery, material cost, manpower cost, recurring mould cost among other issues are making India under competitive as compared to its international competitors in the Indian market. 3D printing is an alternative viable next-generation technology with many advantages over moulding technologies such as no recurring mould cost, better market resilience, lower capital cost per machine etc. The profitability of any business requires full assessment of a manufacturing plant and it varies over time with the movement of demand, supply and production cost. Through this challenge, a benchmark on the most profitable 3D printing business for digital toys will be established for FY2021-22 in India. Further, this business model will help to create economically viable technology for optoelectronic components using 3D printing under CoE AM at CMET, Pune.

Registration: https://forms.gle/5aZsLMioTceccQDo7

Last Date of Submission: 31st December 2021

Result Declaration: 17th January 2022

Documents:

- Grand Challenge Flyer

![[PDF]](/sites/all/modules/filesize_filter/icons/application-pdf.png) 205.32 KB

205.32 KB - Grand Challenge document

![[PDF]](/sites/all/modules/filesize_filter/icons/application-pdf.png) 1.15 MB

1.15 MB

Write to us at coeammeity[at]gmail[dot]com for any enquiry